Reducing the cost of space travel is at the core of SpaceX’s mission to make humanity a multiplanetary species. Central to this ambition is the development of reusable rockets.

As we witness the undeniable progress of Starship launches, a pertinent question arises: Why did SpaceX and choose methane as the fuel for Starship’s Raptor engines instead of more popular choices?

This article examines the reasoning behind this decision and its role in advancing SpaceX’s vision of making humanity a multiplanetary species.

Evaluating SpaceX’s Rocket Fuel Choices

To understand why SpaceX views methane as a key element of its strategy, it’s essential to shift from an Earth-centric perspective. Traditional metrics like cost and specific impulse (Isp), while important, are insufficient when evaluating fuels for interplanetary missions.

SpaceX’s vision goes beyond Earth, requiring a system capable of reliably transporting humans to Mars and back. Achieving this goal means addressing the added complexity, infrastructure demands, and costs inherent in interplanetary travel. Selecting the right fuel is a crucial part of overcoming these challenges.

RP-1 (Rocket Propellant-1, or refined kerosene)

Early space missions relied on RP-1 for its high energy density, which allowed for compact fuel tanks and efficient storage. This made kerosene a practical choice for early designs.

However, RP-1’s long-chain hydrocarbons result in incomplete combustion, producing soot that can accumulate in engine components. For reusable systems, particularly on Mars where repair facilities are unavailable, this poses significant operational challenges.

Liquid Hydrogen

Liquid hydrogen offers a much higher specific impulse (Isp), enabling superior thrust efficiency. However, its extremely low density necessitates much larger fuel tanks, adding mass and complexity to spacecraft designs.

Its cryogenic nature further complicates storage, requiring heavily insulated tanks and boil-off valves to manage pressure buildup. These factors make liquid hydrogen less practical for fully reusable systems, especially for interplanetary missions.

Liquid Methane

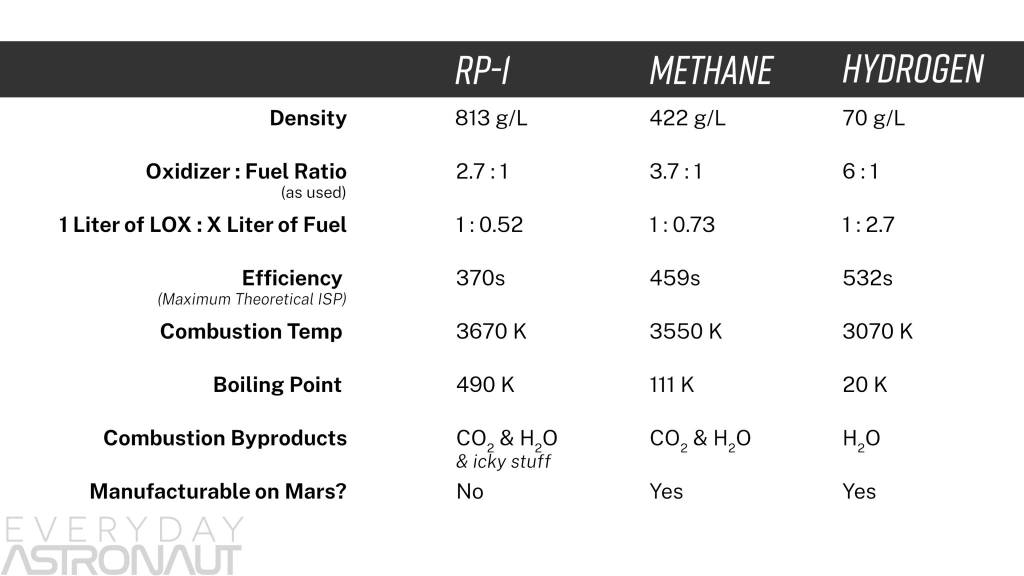

In fact, if you look at the table comparing rocket fuels, methane sits in an intermediate position between RP-1 and liquid hydrogen across multiple metrics.

Methane offers a balance between RP-1 and liquid hydrogen across multiple metrics. Its density (422 g/L) allows for more compact tanks compared to hydrogen, while its specific impulse (459 seconds) is higher than that of RP-1. Methane’s moderate combustion temperature (3550 K) reduces engine stress, and its boiling point (111 K) simplifies cryogenic storage compared to hydrogen.

Source: https://everydayastronaut.com/raptor-engine/

Initially, the primary advantage of methane was seen in its compatibility with in-situ resource utilization (ISRU) on Mars. As we know, Mars’ atmosphere, which is 95% carbon dioxide, theoretically enables methane production via the Sabatier process.

However, as we’ll demonstrate shortly, significant challenges remain despite efforts in this direction. Extracting water from Martian ice caps or soil presents substantial technological hurdles, and no mature technology currently exists to make this process feasible.

In-Situ Resource Utilization (ISRU) on Mars: Unresolved Challenges

In-Situ Resource Utilization (ISRU) was considered one of the most promising strategies for sustaining human presence on Mars, focusing on harnessing local resources to produce critical materials like fuel and water.

The choice of methane as a fuel becomes apparent when considering Mars’ atmosphere, composed of 95% carbon dioxide (CO₂). Through the Sabatier process, CO₂ can be combined with hydrogen to produce methane (CH₄) and water (H₂O). This reaction, facilitated by a catalyst under high temperatures and pressure, provides a theoretically efficient pathway for synthesizing fuel directly on Mars.

Yet, as is often the case with promising theories, practical execution reveals significant hurdles. Methane synthesis via ISRU depends on two primary resources:

- Carbon Dioxide (CO₂): Abundant and readily accessible in Mars’ atmosphere.

- Hydrogen (H₂): A critical bottleneck, as large-scale extraction or production on Mars remains technologically immature and highly challenging.

In the broader context of interplanetary missions, methane balances performance and practicality. Its intermediate density, specific impulse, and clean combustion make it the strongest candidate for fully reusable systems like Starship. These advantages solidify methane’s role in interplanetary travel.

While ISRU remains a vital strategy for utilizing local resources across many applications, when it comes to methane production on Mars, it may not be the most viable or mature solution available. There is an alternative approach—one that leverages a well-established technology already capable of addressing the challenges of methane production for Martian missions. This will be explored in the next section.

Waste-to-Fuel: A Viable Alternative for Methane Production

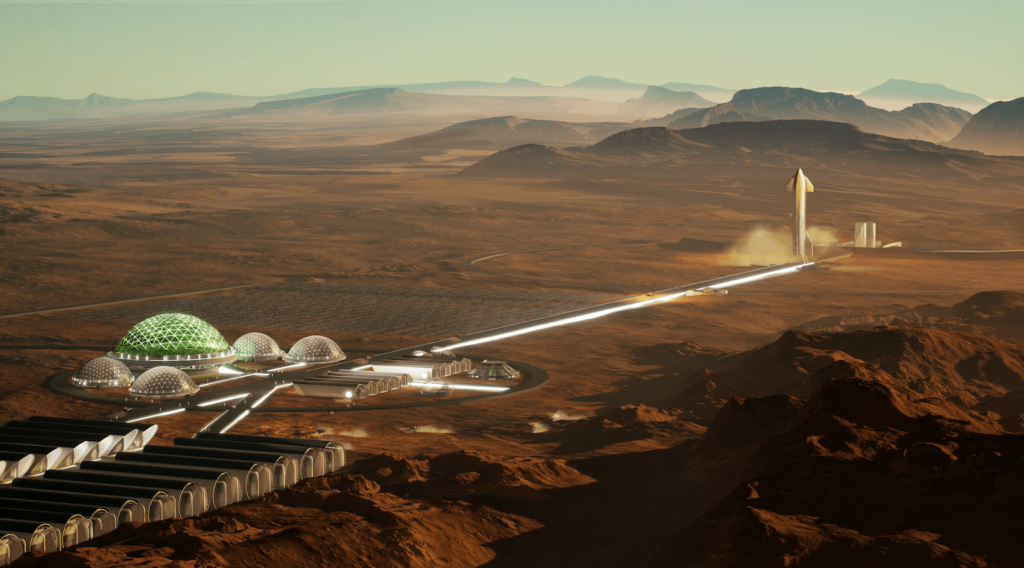

SpaceX has ambitious plans to launch five uncrewed Starship missions to Mars within the next two years, with these numbers expected to grow significantly as Earth and Mars align during subsequent transit windows.

Elon Musk has stated, “Eventually, there will be thousands of Starships going to Mars.” This scale of operations will inevitably generate a substantial amount of waste, ranging from organic materials to packaging and discarded equipment.

This waste presents an opportunity.

Remember when hydrogen was identified as the critical bottleneck for methane production using ISRU?

Waste-to-fuel technology bypasses this limitation entirely by converting diverse waste types—such as plastics, organics, and packaging—into renewable products like synthetic fuels, light hydrocarbons, and syngas.

From this synthetic gas, methane can be extracted directly, offering a solution that is not only technologically mature but also operationally practical for near-term Martian missions.

By adopting this approach, SpaceX would be able to advance its vision, achieve greater independence, reduce logistical challenges, and lay the foundation for a multiplanetary future.